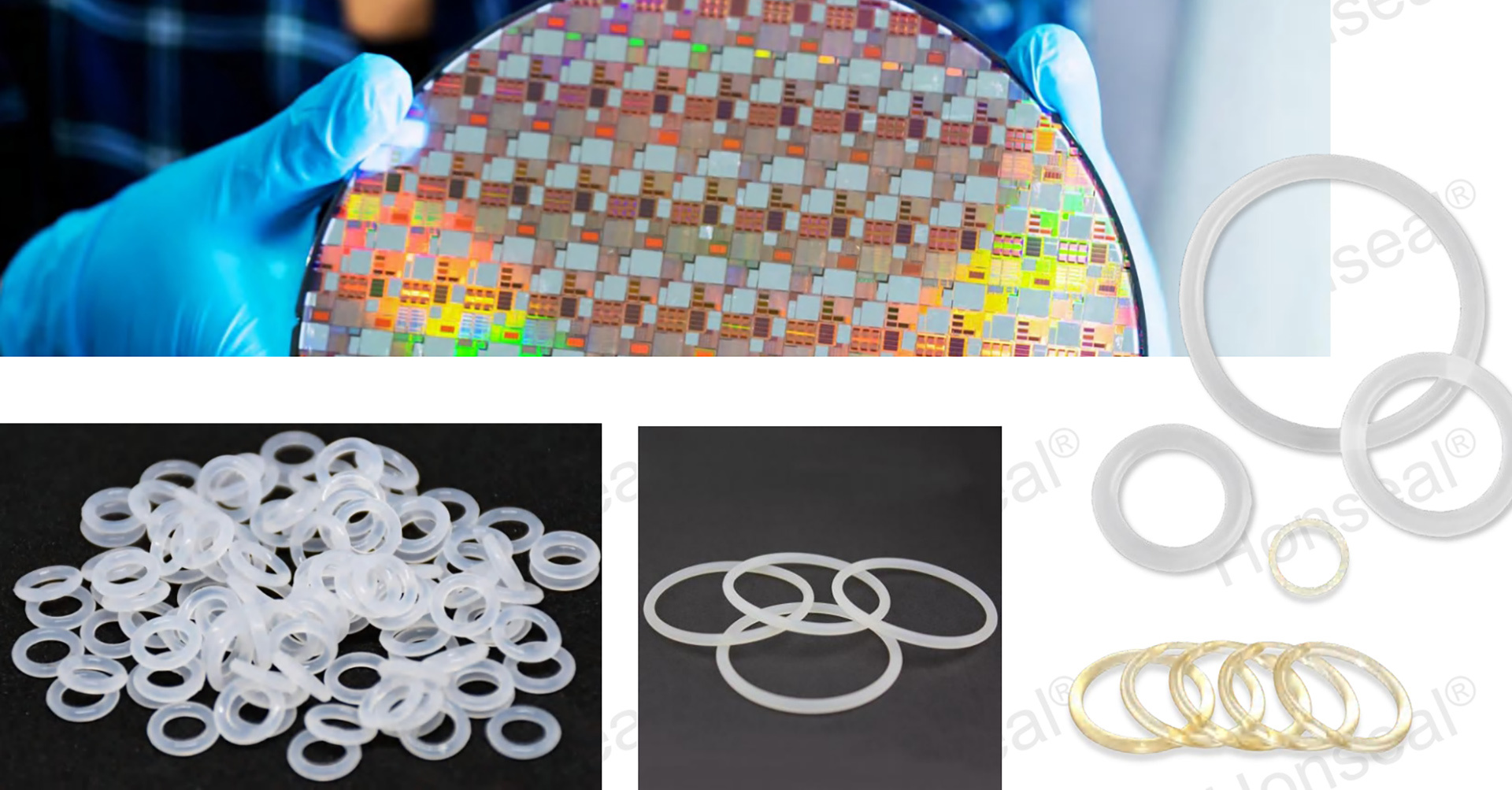

Application areas

Semiconductor

FFKM materials are very suitable for plasma, CVD (chemical vapor deposition) and thermal and wet processes, such as etching, HDPCVD (high density plasma chemical vapor deposition), PECVD (plasma enhanced chemical vapor deposition), LPCVD (low pressure chemical vapor deposition), RTP (rapid thermal processing), wet etching, cleaning, photoresist stripping, copper plating processes, etc.Honseal O-rings provide engineers with high-performance sealing components for a variety of static and dynamic applications.

As the semiconductor industry continues to evolve and grow in complexity, the demands on seals and sealing systems are also increasing. Our FFKM materials are exceptionally well-suited for the extreme conditions encountered in semiconductor processing, whether it's handling corrosive chemicals or high-energy systems. Through our proprietary polymer and curing systems, we are able to streamline the variety of FFKM materials required for a wide range of applications.

Hongxin Fluoroether can provide cost-engineered solutions for your applications. Our unique curing and material formulations are vertically integrated back to the monomer level, delivering superior performance along with advantages in cost and delivery.

|

Application Process |

Application Technology |

Process Temperature |

kalrez | Chemrez | Honseal | Application |

|

Wet Process |

Wafer Preparation |

25-125 | 8085 6375UP 6375 |

E38 513 |

7501W1 7561W1 7561B1 7562B2 |

Vavle Seal Drain Seal Flow Meters Seals for Containers |

|

Etching |

25-200 | |||||

|

Photolithography |

25-150 | |||||

|

Stripping |

25-150 | |||||

|

Copper Plating |

25-150 | |||||

|

Low Temperature Processing |

-40-200 | 0040 |

860 870 |

7001B0 | ||

|

Plasma Processing |

HDP-CVD PE-CVD |

25-200 | 9100 Zalak P770 4079 8475 |

XRZ 657 |

7001W3 7501T2 7501W1 7261B3 |

Dynamic Seal: Static Seal: |

|

Dry Etching |

25-200 | |||||

|

Ashing/Stripping |

25-250 | |||||

|

Thermal Processing |

SA-CVD |

25-300 | 8085 | 657 | 7504W1 7501W1 7501T2 7501T4 7501W2 |

|

| ALD LP-CVD |

25-300 | 9100 | ||||

| 0xidation Diffusion |

100-300 | |||||

| Lamp Annealing RTP |

100-300 | 8475 |

Honseal FFKM Selection Guide

| 牌号/GradeName | Honseal-7562B2 | Honseal-8001B4 | Honseal-8001W2 | Honseal-7502W3 | Honseal-7503B3 | Honseal-7504B3 | Honseal-7501A1 | Honseal-7505B3 | Honseal-7501B1 | |

| Kalrez对应牌号 | Kalrez 6375UP |

Kalrez 7075up |

Kalrez 8085 |

Kalrez 8475/8575 |

Kalrez 8700 |

Kalrez 8900 |

Kalrez 9100 |

Kalrez 9300 |

Kalrez W240UP |

|

| 颜色/Color | 黑色/black | 黑色/black | 白色/white | 白色/white | 黑色/black | 黑色/black | 琥珀/Amber | 棕色/brown | 黑色/black | |

| 基本物性/PhysicalProperty | 硬度/Hardness, Shore A | 74.6 | 80 | 81 | 74 | 78 | 78 | 77 | 76 | 74 |

| 拉伸强度/Tensile Strengt (MPa) | 15.5 | 20.1 | 17.6 | 13.6 | 25 | 23.1 | 18 | 17.3 | 21.3 | |

| 伸长率/Elongation (%) | 180 | 160 | 260 | 208 | 170 | 150 | 166 | 239 | 210 | |

| 100%定伸/100% Modulus (Mpa) | 8.5 | 12 | 7.92 | 5.24 | 10.5 | 12.5 | 7.4 | 4.92 | 7.3 | |

| 密度/Density | 2.03 | 2.02 | 2.03 | 2.02 | 2.01 | 2.03r | 2.02 | 2.06 | 2.03 | |

| 压变/CompressionSet | 25 200℃ 70hr |

53 325℃ 70hr |

46.3 200℃ 70hr |

12.9 250℃ 70hr |

30 315℃ 70hr |

19.5 280℃ 70hr |

20 250℃ 70hr |

12 250℃ 70hr |

20 200℃×70hr |

|

| 最高使用温度/MAX | 280 | 325 | 280 | 300 | 325 | 315 | 300 | 300 | 230 | |