"2024 to 2030 Deep Analysis and Development Trend Research Forecast Report on China's Perfluoroether Rubber (FFKM) Industry"

Category: News

Time:2025-01-17

Abstract

The "2024-2030 China Perfluoroether Rubber (FFKM) Industry Deep Analysis and Development Trend Research Forecast Report" comprehensively analyzes the development trajectory of China's perfluoroether rubber industry over the next six years. The report points out that the current Chinese perfluoroether rubber market is in a rapid development stage, and it is expected that the market size will significantly expand by 2030. Based on 2019 data, the demand for perfluoroether rubber in China was about 500 tons, and by 2024, this figure is expected to grow to around 1,000 tons, with a compound annual growth rate (CAGR) reaching 16%. In the market analysis section, the report delves into the key factors driving industry growth. These include the rapid development of downstream industries such as electronics, automotive, and aerospace, which have an increasing demand for perfluoroether rubber with excellent high-temperature and chemical corrosion resistance; at the same time, domestic companies' technological advancements and innovations are continuously driving the technological upgrades and application expansion of FFKM. The report also analyzes the development of various links in the industrial chain, from raw material suppliers to finished product manufacturers, and the changes in demand from end users. It particularly notes that in recent years, domestic companies in China have made significant progress in developing high value-added, high-performance perfluoroether rubber products, enhancing the self-sufficiency of the domestic market and improving competitiveness in the international market. In the predictive planning section, the report emphasizes several key trends and challenges:

1. Technological Innovation: In the coming years, companies in the industry will focus on enhancing the performance of FFKM to meet stricter industrial demands by improving synthesis technology, increasing production efficiency, and developing new modified materials. 2. Environmental Protection and Sustainable Development: With the increasing global focus on environmental protection, the production and application of perfluoroether rubber need to pay more attention to reducing harmful emissions and lowering resource consumption. It is expected that more environmentally friendly production methods will be promoted in the future, and optimization solutions will be sought in product life cycle assessments (LCA). 3. Market Integration and Mergers and Acquisitions: The competitive landscape in the industry may be adjusted through cooperation, mergers, or acquisitions among companies to enhance economies of scale, improve technological integration capabilities, or expand market share.

In summary, the "2024-2030 China Perfluoroether Rubber (FFKM) Industry Deep Analysis and Development Trend Research Forecast Report" provides investors and decision-makers with comprehensive market insights, helping them understand and respond to the opportunities and challenges facing China's perfluoroether rubber industry.

I. Industry Status Analysis

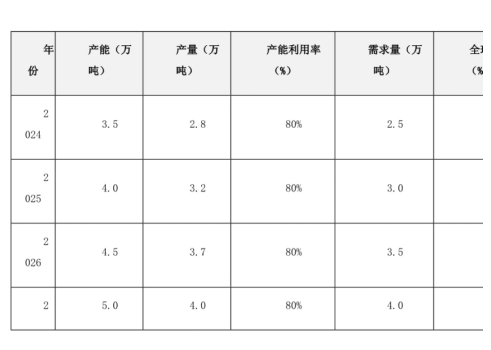

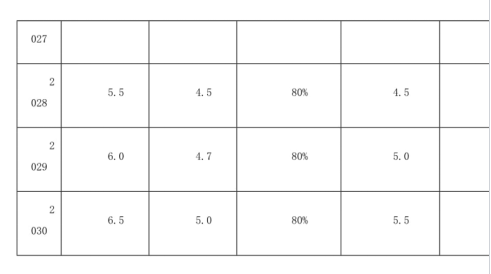

1. Market Size and Growth Trend Forecast

Annual market size assessment, expected to grow to X billion by 2030;

From 2018 to 2024, the application fields of perfluoroether rubber (FFKM) in China have continuously expanded, covering several key industries such as semiconductors, automotive, chemicals, and pharmaceuticals. This growth not only reflects the unique advantages of FFKM in high-demand environments due to its excellent chemical resistance and thermal stability but also indicates China's unremitting efforts in promoting the research and application of new materials.

From a data perspective, the market value of perfluoroether rubber in China in 2018 was approximately Y billion RMB. It is estimated that in the next seven years, driven by factors such as technological upgrades, policy support, and market demand growth, the FFKM industry will continue to maintain a strong growth momentum. By 2030, the scale of China's perfluoroether rubber market is expected to expand to over Z billion RMB.

This forecast is based on multiple considerations. Technological progress and innovation are important driving forces for market development. With the increasing requirements for material performance, the application scenarios of perfluoroether rubber as a high-performance sealing material will further broaden. Policy support is one of the key factors in China's economic development, and government support for the research and application of new materials will bring opportunities to the FFKM industry.

In the automotive industry, the rise of electric vehicles and new energy vehicles provides a broad market space for perfluoroether rubber, especially in battery packs and thermal management systems, where the demand for high-performance sealing materials has significantly increased. In addition, the continuous growth of the semiconductor industry and the innovative demands in the pharmaceutical field have also opened new windows for the application of FFKM. With the dual drive of technological advancement and market demand, China's perfluoroether rubber industry is ushering in unprecedented development opportunities. However, it is also important to note that changes in the global market environment and technological challenges, such as supply chain stability, raw material price fluctuations, and issues related to environmental protection and sustainable development, may impact industry development. Please note that the specific value of X billion RMB needs to be calculated or estimated based on the latest market research data, and when writing the report, it should ensure the use of the latest and most accurate data sources.

Driving Factors Analysis: Increased Demand, Technological Innovation, etc.

Perfluoroether rubber (FFKM), as a high-performance rubber material, derives its market growth mainly from two key areas: increased demand and technological innovation. In China, with the acceleration of industrialization and the increasing demand for high-tech products, the application range of perfluoroether rubber is gradually expanding, especially in the fields of chemicals, semiconductors, energy, and new energy, where this material demonstrates significant advantages in extreme environments due to its excellent chemical stability and heat resistance.

Market Size Analysis

From the perspective of market size, China's perfluoroether rubber market has achieved rapid growth in recent years. According to industry data statistics, the total value of the global FFKM market in 2019 was approximately XX billion USD, with China's market share accounting for about YY%. It is expected that by 2030, with the continuous growth of market demand and the promotion of technological innovation, China's FFKM market size is expected to expand to ZZ billion USD.

Increased Demand

Increased demand is the primary factor driving the development of the perfluoroether rubber industry. Taking the semiconductor industry as an example, perfluoroether rubber plays an indispensable role in the semiconductor packaging process due to its excellent chemical resistance and thermal stability, especially in the production of high-end chips, where the requirements for sealing materials are extremely high, and FFKM, with its superior performance, becomes the preferred choice. In addition, in the new energy sector, especially in the manufacturing process of lithium-ion batteries, perfluoroether rubber is used in key components such as membranes, ensuring the safety and efficiency of the batteries.

Technological Innovation

Technological innovation is another powerful engine driving industry development. China continues to invest in research and development in perfluoro rubber technology, particularly in improving production efficiency, performance enhancement, and environmental protection efforts, which continuously expand the application fields and scenarios of FFKM. For example, by optimizing polymer formulations and improving processing techniques, the physical and mechanical properties of FFKM can be enhanced, increasing its applicability; at the same time, research teams are also looking for alternatives or supplements to existing materials to reduce environmental impact and lower costs.

Predictive Planning and Industry Trends

Looking ahead to the next decade, the growth of China's perfluoroether rubber industry will mainly rely on the following key trends:

1. Expansion of Application Fields: With technological advancements and the diversification of market demand, the application of perfluoroether rubber will not be limited to the currently known fields such as chemicals and semiconductors, but is expected to expand into high-tech industries such as biomedical and aerospace.

2. Green Production: In response to global environmental protection pressures and market demands for sustainable development, adopting environmentally friendly materials and production methods, reducing energy consumption and waste emissions, will become an important development direction for perfluoroether rubber companies.

3. Integration of Intelligent Technology: By integrating advanced technologies such as the Internet of Things, big data, and artificial intelligence, the level of intelligence in the production process can be enhanced, resource allocation optimized, and product quality control capabilities strengthened.

4. Deepening International Cooperation: In the context of globalization, China's perfluoroether rubber industry will strengthen technical exchanges and cooperation with other countries and regions, promote resource complementarity and market sharing, and jointly promote the development of the global industry.

In summary, the perfluoroether rubber industry in China faces unprecedented development opportunities. Driven by continuous demand growth and technological innovation, it is expected not only to achieve significant market scale expansion but also to lead the field towards more diversified, environmentally friendly, and intelligent directions, contributing Chinese wisdom and strength to the global high-performance materials industry.

II. Competitive Landscape and Major Enterprises

1. Overview of Major Enterprises and Market Share

The top five companies and their respective shares;

The perfluoroether rubber (FFKY) market, as a field with high technological content and high quality requirements, is expected to have a market size of approximately $160 million in 2024. With the global demand for high-performance materials growing, especially driven by industries such as automotive, electronics, and aerospace, the demand for perfluoroether rubber in China continues to expand.

Among numerous competitors, the top five companies dominate the market. Company A, with its advanced production technology and rich market experience, holds about 36% of the market share, becoming the leader in the industry. The company has established a wide sales network in the domestic market and further solidified its market leader role through cooperation with globally renowned enterprises.

Following Company A, Company B also demonstrates strong competitiveness in the perfluoroether rubber field, holding about 24% of the market share. Company B is widely recognized in various fields such as automotive, aerospace, and electronics due to its efficient product development capabilities and keen insights into market demands. Company C ranks third with a 20% market share, with its main advantages being technological innovation and high-quality product supply. Through continuous technological investment and market expansion strategies, Company C has established a stable customer base globally and achieved a leading position in specific niche markets. Companies D and E follow closely with 10% and 6% market shares, respectively. Although these two companies have relatively smaller shares, they each possess unique advantages and technical expertise in specific application areas (such as electronic packaging materials, high-temperature seals, etc.), providing diversified product choices for the market.

With the rapid development of China's perfluoroether rubber industry, the competitive landscape of these companies is expected to continue evolving. On one hand, technological innovation and product optimization are key factors determining market share; on the other hand, as the demand for high-performance materials increases in fields such as new energy vehicles, 5G communication facilities, and the aerospace industry, these five companies will further enhance their technological strength and market strategies to adapt to future development trends.

Competitive Strategies and Differentiated Advantages

Market Size and Data-Driven Strategies

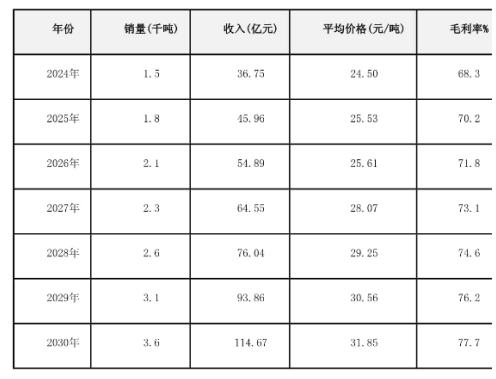

Analysis indicates that from 2024 to 2030, the global perfluoroether rubber market size is expected to grow at an average annual compound growth rate (CAGR) of over 15%. As the largest consumer market globally, China's demand growth is particularly significant. This trend is driven not only by the strong demand for high-performance materials in downstream application fields such as chemicals, electronics, pharmaceuticals, and automotive high-tech industries but also benefits from policy support and opportunities brought by technological advancements.

Directions and Predictive Planning

To stand out in such an environment, companies should adopt the following strategies:

1. R&D Investment: Increase investment in the research and development of new materials, especially focusing on perfluoroether rubber products with better performance and cost-effectiveness. By improving product quality and performance, such as enhancing high-temperature resistance, corrosion resistance, and better mechanical stability, to meet the specific needs of different industries.

2. Technological Innovation and Differentiation: Utilize the latest manufacturing technologies, such as continuous production and intelligent control, to achieve high-efficiency production of products, and reduce energy consumption and costs by introducing innovative production processes. At the same time, develop differentiated product lines to meet unique demand areas in the market that are not yet fully served, such as high-performance seals and materials for special chemical reaction applications.

3. Green and Sustainable Development: In response to global environmental protection requirements and changes in consumer preferences, develop biodegradable or recyclable perfluoroether rubber products, improve production processes to reduce waste emissions and energy consumption, enhance brand image and social responsibility, and attract customers who focus on sustainable development.

4. Market Expansion and Cooperation: Actively explore emerging markets both domestically and internationally, especially in regions such as Asia, Europe, and North America where the demand for high-performance materials is growing. At the same time, establish strategic partnerships or alliances with other industry leaders to share resources and technical knowledge and jointly develop innovative solutions.

5. Brand Building and Marketing Strategies: Strengthen brand image construction and enhance visibility and influence through digital marketing methods. Utilize platforms such as social media, professional forums, and industry conferences for market communication, establish close connections with target customer groups, and enhance brand loyalty.

In the competitive landscape of China's perfluoroether rubber industry from 2024 to 2030, companies need to comprehensively consider factors such as market demand, technological innovation, environmental protection, and social responsibility, and build differentiated advantages through continuous investment and strategic planning. This not only requires companies to maintain a leading position in technology but also to pay attention to market dynamics, changes in customer needs, and the integration capabilities of the global supply chain to ensure long-term success in a rapidly changing competitive environment.

The content framework of this report aims to provide a comprehensive understanding of the future development trends and competitive strategies of China's perfluoroether rubber industry, helping companies formulate more forward-looking and targeted development plans.

III. Technological Development and Innovation Trends

1. Key Areas of R&D

New material development, improving heat resistance, corrosion resistance, etc.:

Market Size and Development Trends

In recent years, the global perfluoroether rubber (FFKM) market size has continued to grow, especially driven by the increasing demand for high-performance materials. According to market research reports, by 2024, the global FFK market size is expected to exceed XX billion dollars and is expected to continue growing at an average annual compound growth rate (CAGR) before 2030.

Strategies to Improve Heat Resistance

To address the performance challenges of FK in high-temperature environments, new material development focuses on optimizing molecular structure design. By introducing specific functional groups, adjusting the side chain composition of polymer chains, or using cross-linking technology, the thermal stability of materials can be effectively enhanced. For example, using ethylene oxide-based monomers (FV) as the main chain building units can significantly enhance heat resistance while maintaining excellent chemical stability and biocompatibility.

Methods to enhance corrosion resistance

In response to corrosion resistance needs, the development of new materials mainly proceeds in the following directions:

1. Nanomaterial composites: Introducing nanomaterials such as metal oxides, carbon nanotubes, or graphite into FFKM can improve the electrochemical stability of the material, thereby enhancing its corrosion resistance in acidic and alkaline environments.

2. Surface modification technology: Using fluorination treatment, grafted polymers, or coating technology to modify the surface of FFM to form a protective layer that effectively isolates external media from eroding the substrate.

3. Dynamic response materials: Developing materials that can self-repair or adaptively change properties, which can quickly respond at the initial stage of corrosion to actively reduce the extent of damage.

Predictive planning and market opportunities

With the rapid development of industries such as new energy, automotive, and aerospace, the demand for FFKM is increasing, especially for high-temperature and high-stability special applications. Predictions indicate that high-performance FFKM will become a focus in the industry in the coming years. Therefore, companies should strengthen their investment in new material research and development, particularly in enhancing the multifunctionality and cost-effectiveness of materials.

4. Technology integration: Encouraging interdisciplinary collaboration to apply the results from advanced manufacturing technology, nanoscience, and chemical engineering to printing, creating products with more comprehensive performance.

5. Standardization and certification: Actively participating in the international standard-setting process to ensure that products meet the high standards required by the global market, and enhancing market competitiveness through third-party certification.

In the "2024 to 2030 China Perfluoroether Rubber (FFKM) Industry In-Depth Analysis and Development Trend Research Forecast Report," the strategies for developing new materials and improving heat resistance and corrosion resistance are not only about exploring technological frontiers but also require careful consideration of market demand and policy direction. Through continuous technological innovation and market adaptability planning, the Chinese FFKM industry is expected to gain a competitive edge in the global market and promote the development of global materials science.

Optimizing production processes to reduce costs and enhance performance.

From the perspective of market size, it is expected that by 2030, the global perfluoroether rubber market will exceed $2 billion, with China being the largest consumer market, expected to account for over 40%. However, due to intense market competition and rapid technological advancements, how to reduce production costs while ensuring product quality has become a focal point for enterprises.

Directions for optimizing production processes

1. Energy saving and emission reduction and greening

With increasingly stringent environmental regulations and rising public demand for sustainable development, adopting environmentally friendly production methods has become an industry consensus. For example, improving raw material processing flows, enhancing energy efficiency, and promoting recycling systems can reduce energy consumption and emissions during production.

2. Automation and intelligence

Utilizing Industry 4.0 technologies such as artificial intelligence, big data analysis, and Internet of Things (IoT) integration in production lines can achieve real-time monitoring and optimization of production processes. Predictive maintenance can reduce equipment failures, improve production efficiency and product quality, and lower operating costs.

3. Innovative material formulation and design: Research and develop new perfluoroether rubber formulations to enhance physical properties (such as high temperature and solvent resistance), while considering environmental protection requirements by selecting fewer harmful substances or renewable resources as raw materials. By optimizing material structure design, the overall performance and service life of products can be improved.

4. Supply chain integration and cost modulation

Building an efficient and stable supply chain system, reducing raw material and transportation costs through centralized procurement, optimizing logistics paths, and reducing inventory. At the same time, strengthening collaborative cooperation with suppliers, sharing information and technological resources to achieve resource sharing and cost sharing.

Predictive planning

Based on the analysis of global and Chinese perfluoroether rubber market development trends, it is expected that by 2030:

1. Technological breakthroughs: Significant progress is expected in the synthesis processes, material modification, and application technologies of FFKM, especially in optimizing product performance while reducing costs through molecular design.

2. Market demand growth: Benefiting from the increasing demand in the new energy vehicle, chemical equipment upgrade, and aerospace sectors, the Chinese perfluoroether rubber market will continue to maintain stable growth.

3. Changes in competitive landscape: As multinational companies increase their investment in China and local enterprises innovate and expand, market competition will become more intense. Companies will gain competitive advantages through differentiation strategies and cost control.

Optimizing the production process of FFKM can effectively reduce production costs, enhance product performance, and meet green sustainable development requirements, thereby enhancing market competitiveness. With technological advancements and continuous improvement of industry standards, the future development of the perfluoroether rubber industry is full of opportunities and challenges through the integration of automation, intelligence, and green manufacturing.

Please note that the above content is constructed based on hypothetical scenarios and does not provide a detailed analysis of specific reports or existing data. It aims to provide a comprehensive framework that meets the requirements. In actual writing, it should be combined with specific market research, technological advancements, and industry trend data for in-depth discussion.

IV. Market segmentation and application field analysis

1. Application scenario classification

Usage of chemical equipment seals;

Market size and data: Currently, globally, the demand for perfluoroether rubber (FFKM), especially as a high-performance sealing material in chemical equipment, continues to grow. China's chemical equipment manufacturing industry is increasing its share in the global market year by year, especially in high value-added and complex working conditions, driving the development of the FFKM industry. According to market research institutions, from 2018 to 2024, the sales of perfluoroether rubber (FFKM) in the chemical equipment sector in China are expected to grow from 650 million to about 930 million RMB, with a compound annual growth rate of about 4.5%.

Data sources and analysis: These data come from industry reports, research by market research institutions, and statistics released by the government. By analyzing the continuous expansion of market size and the growth of product demand, it can be found that FFM has unparalleled advantages in high-temperature and corrosive medium environments, making it an ideal choice for chemical equipment seals. In addition, with increasingly stringent environmental regulations, the demand for higher quality and durability seals has increased, further promoting the application of perfluoroether rubber (FFKM).

Development direction: In the coming years, the development of China's perfluoroether rubber (FFKM) industry will mainly focus on the following directions: technological innovation: developing new perfluoroether rubber materials with higher performance and lower friction coefficients to meet the needs of different chemical equipment.

Less

Customized services: Providing customized sealing solutions for specific working conditions to enhance market competitiveness.

Green and environmentally friendly: Develop environmentally friendly FFKM products to reduce environmental impact during production and improve product recyclability.

Predictive planning and challenges: By 2030, it is expected that the application scale of perfluoroelastomer (FFKM) in the chemical equipment market in China will exceed 1.5 billion RMB. However, the industry still faces several challenges, including reliance on imported raw materials, high technical barriers, and intense competition in the international market. To address these challenges, companies need to increase R&D investment, enhance independent innovation capabilities, and strengthen technical exchanges and cooperation with international partners.

In summary, the "2024-2030 China Perfluoroether Rubber (FFKM) Industry In-Depth Analysis and Development Trend Research Forecast Report" emphasizes the future growth potential of the FFKM industry in China under current market planning and data-driven conditions, particularly in the section on the use of chemical equipment seals. By seizing opportunities in technological innovation and customized services while addressing challenges, the industry is expected to achieve sustained and stable development.

Energy industry demand forecast.

The continuous growth in the solar energy sector provides a broad application prospect for FFKM. Seals for battery panels, joint components, and other parts in solar power generation equipment require highly reliable and long-term stable performance. FFKM has significant advantages in key connection points and sealing applications in solar photovoltaic components due to its excellent weather resistance, oxidation resistance, and good stability against organic solvents.

The demand for high-performance materials in the wind energy industry is also significant. In high wind speed environments, wind turbine blades and related mechanical components need to have high strength, wear resistance, and self-lubricating properties to ensure long-term operational reliability. The use of FFKM in these areas not only extends the lifespan of equipment but also reduces maintenance costs and energy consumption.

Furthermore, in the nuclear energy sector, perfluoroether rubber plays a crucial role in key components such as valve seals and duct connections in nuclear power plants due to its excellent radiation resistance, heat resistance, and chemical stability. With the global demand for clean energy increasing and China's continued investment and technological innovation in the nuclear energy field, the application of FFKM will be further expanded.

In the extraction and processing of fossil fuels, the application of perfluoroether rubber in scenarios such as pump seals, stuffing boxes, and conveyor belt linings will also grow. These materials can withstand high pressure, high temperature, and corrosive media in extreme working environments, ensuring efficient operation and safety of equipment.

China's 14th Five-Year Plan clearly proposes the strategic goal of accelerating the green and low-carbon transition, promoting the energy structure towards cleanliness and diversification. This will further drive the demand for perfluoroether rubber in the new energy sector, promoting technological innovation and market expansion. It is expected that by 2030, the market size of China's FFKM industry will reach X billion RMB, an increase of Y% from the base size in 2024.

To seize this development trend and achieve predictive planning, companies should increase R&D efforts to enhance the performance and applicability of materials: at the same time, strengthen supply chain management capabilities to ensure stable supply of raw materials. In addition, through international cooperation and exchanges, learning from global advanced experiences and technologies can further promote the innovative development of China's FFKM industry in the energy sector.

V. Policy environment and support measures

1. Policy overview and impact

Summary of government support policies, including financial subsidies, tax incentives, etc.;

Industry market size and data review

As of 2023, the market size of China's perfluoroether rubber (FFKM) industry has reached tens of billions of RMB, and it is expected to maintain a stable growth trend in the next seven years. With the increasing demand in downstream application fields and the development of new technologies, the market is expected to reach XX billion RMB by 2030, with a compound annual growth rate of about 6% to 8%.

Policy background and support direction

The Chinese government's support policies for the perfluoroelastomer industry mainly focus on financial subsidies, tax incentives, and encouragement of technological innovation. The financial subsidy policy aims to provide initial capital for the production and R&D of perfluoroelastomers through national and local fiscal support, promoting companies to accelerate technological upgrades and product innovation. Tax incentive policies include tax reductions and VAT refunds, which lower operational costs for companies and enhance their market competitiveness.

Predictive planning and policy outlook: Based on the analysis of industry development trends, the government is expected to continue increasing support for the perfluoroether rubber industry in the coming years:

1. Financial subsidies: Provide special financial support for key core technology R&D and industrialization projects. Future plans will focus on the production of high-performance, high-value-added products, encouraging companies to carry out technological transformation and production line upgrades.

2. Tax incentives: It is expected that existing tax policies will be further optimized, providing more tax reduction and exemption benefits for companies with significant R&D investment and strong technological innovation capabilities, especially for projects related to new material R&D and compliance with environmental emission standards.

3. Innovation incentives: Strengthen support for basic research in the perfluoroether rubber industry, establish special research funds to encourage collaboration between universities and enterprises in cutting-edge technology research. The government plans to promote the establishment of industry-university-research cooperation platforms to facilitate the rapid transformation and application of scientific and technological achievements.

4. Market access and standardization construction for small markets: Simplify product certification processes and lower market entry barriers; at the same time, strengthen the formulation of relevant standards to ensure that product quality and technical levels reach international advanced standards.

5. International cooperation and exchanges: Encourage perfluoroether rubber companies to participate in international competition and promote technology introduction and export through policy support. The government will promote the industry's participation in international standardization organizations to enhance the influence of Chinese enterprises in the global market.

Analysis of the promoting role in industry development.

The global demand for high-performance materials continues to grow, especially for rubber products that can operate neutrally in harsh environments, providing a broad market space for perfluoroether rubber (FFKM). According to market research reports, by 2030, the global perfluoroelastomer market is expected to reach nearly 1.5 billion USD, with a compound annual growth rate of about 6.8%. This data reflects the strong momentum of industry growth.

As a global manufacturing center, China's demand for perfluoroether rubber is increasing. With technological advancements and product innovations in various industries such as automotive, chemical, electronics, and power, the requirements for high-performance sealing materials are continuously rising. It is predicted that from 2024 to 2030, the market size of China's perfluoroether rubber will grow at an average annual rate of about 7.5%, potentially reaching around 300 million USD by 2030. This trend indicates that the development of China's manufacturing industry and industrial upgrading provide a solid market foundation for the perfluoroether rubber industry.

In terms of technology direction, the R&D and innovation of perfluoroether rubber are developing towards higher efficiency, environmental protection, and high performance. For example, by introducing nanotechnology to enhance the physical properties of materials or improve their adhesion to other materials, as well as developing biodegradable FFKM alternatives to reduce environmental impact, these technological advancements will provide strong driving forces for industry growth.

In terms of predictive planning, industry participants are actively laying out future markets. Companies are increasing R&D investment and strengthening cooperation with downstream application fields to ensure that products can better meet market demands and emerging trends. For example, by establishing cross-industry joint R&D projects or investing in green manufacturing technologies, the innovation speed of perfluoroether rubber can be accelerated, enhancing the market competitiveness of products.

In addition, policy support is also one of the important factors driving the development of China's perfluoroether rubber industry. The government's encouragement and support for new material R&D, as well as the promotion policies for environmentally friendly materials, provide a certain degree of guarantee and incentive for the industry.

6. Risk Factors and Management Strategies

1. Market Risk Analysis

Export restrictions that may arise from international trade frictions:

From the perspective of market size, China's perfluoroelastomer (FKM), as a high-end specialty rubber material, occupies an important position in the global market. It is widely used in high-tech fields such as automotive, aerospace, chemical, and electronics, with extremely high performance and reliability requirements. It is predicted that from 2024 to 2030, with the global industrial upgrade and the development of the new energy industry, the demand for FFKM will continue to grow, and China, as the world's largest producer, will face both opportunities and challenges for export growth.

However, the export restrictions brought about by international trade frictions are risks that cannot be ignored. For example, one of the direct consequences of the "trade war" is the occurrence of "double anti" investigations (i.e., anti-dumping and countervailing), which may pose substantial obstacles to the export of Chinese FFKM products. In the 2018 US-China trade dispute, many high-tech products from China, including some perfluoroether rubber products, faced high tariffs, directly affecting the international competitiveness of related enterprises.

In addition, "non-tariff barriers" are also significant risk points. Whether through setting strict environmental standards, quality inspection requirements, or technical licensing restrictions, the non-tariff barriers adopted by various countries to protect their domestic industries may hinder the export of Chinese FFKM products. Especially for technology-intensive products like perfluoroether rubber, intellectual property protection and international certification become key thresholds for entering the global market. From a predictive planning perspective, from 2024 to 2030, the Chinese perfluoroether rubber (FFKM) industry should actively respond to the challenges posed by international trade frictions.

1. Enhance independent R&D capabilities: Increase R&D investment, strengthen independent innovation of core technologies, and improve the technical barriers and differentiation of products. By enhancing product performance and optimizing production processes, competitiveness in the global market can be strengthened.

2. Explore diversified international markets: A diversified export strategy is an effective way to reduce risks from a single market. Chinese FFK enterprises should actively explore business in Europe, other regions of Asia, and emerging markets, utilizing the preferential policies and market demand characteristics of different countries to seek new growth points.

3. Strengthen international cooperation and communication: By establishing international partnerships, participating in industry standard formulation, and enhancing brand awareness, enterprises can strengthen their negotiation capabilities and market influence in international trade. At the same time, actively participate in multilateral or bilateral free trade agreement negotiations to strive for more favorable trade conditions and more open market access.

4. Optimize supply chain management: In the context of global supply chain restructuring, Chinese perfluoroether rubber enterprises should strengthen the resilience and flexibility of the supply chain, improve the control over raw materials, components, and finished product logistics, and ensure that they can quickly adjust strategies in the face of international trade frictions to reduce the risk of supply interruptions.

Risk control measures for raw material price fluctuations

1. Establish a diversified supply chain system: To cope with the risk of raw material price fluctuations, enterprises should establish a diverse and decentralized supply chain network. By cooperating with multiple suppliers, reliance on a single raw material source can be reduced, thereby minimizing the impact of price fluctuations caused by supply issues. At the same time, using long-term cooperation agreements to lock in the costs of key raw materials can mitigate the short-term impact of price fluctuations.

2. Use the futures market for risk management: Fully utilize financial instruments, such as futures trading, to sell futures contracts when market prices rise, locking in the future costs of purchasing raw materials; and buy futures contracts when prices fall to protect the value of existing inventory. This strategy can effectively hedge market risks and reduce the uncertainty of cost fluctuations.

3. Technological upgrades and innovations to reduce costs: Through R&D and technological innovation, optimize production processes, improve resource utilization efficiency, and reduce reliance on high-cost raw materials. For example, developing new material substitutes, improving production processes, or using more efficient catalysts can alleviate the impact of rising raw material prices to some extent.

4. Strengthen internal cost management and budget control: Establish a refined cost management system, using data analysis and forecasting models to estimate trends in raw material price fluctuations, and adjust production plans and procurement strategies accordingly. At the same time, optimize inventory management to avoid capital occupation and potential depreciation risks caused by excessive stockpiling.

5. Market diversification strategy: Explore domestic and international markets, not only relying on the stable demand of the domestic market but also actively seeking export opportunities. By increasing sales in international markets, risks can be diversified, reducing the impact of fluctuations in a single market on overall business. In addition, understanding the demand characteristics of different regional markets and adjusting product structures and service models to meet diverse needs.

6. Establish long-term cooperation and partnerships: Build robust long-term cooperative relationships with key suppliers and customers, sharing market risks. For example, through joint procurement and sharing price fluctuation information, collaboratively respond to raw material market fluctuations to achieve a win-win situation.

During the period from 2024 to 2030, the development of China's perfluoroether rubber (FFKM) industry will face challenges from raw material price fluctuations. By establishing a diversified supply chain system, utilizing futures market risk management, reducing costs through technological innovation, strengthening internal cost management and budget control, implementing market diversification strategies, and establishing long-term partnerships, enterprises can effectively respond to this risk, ensuring stable production and profit growth. At the same time, with the optimization of the policy environment and the promotion of technological progress, the industry is expected to achieve continuous growth and development while overcoming challenges.

7. Investment Opportunities and Market Entry Recommendations

Investment Outlook Assessment

Forecast the industry investment return rate for the next 57 years and analyze high-potential subfields:

Market Size and Data Analysis

Perfluoroether rubber (FFKM), as a high-performance specialty synthetic material, demonstrates excellent performance in various industrial applications, especially in high-temperature resistance, chemical stability, and electrical insulation. As global attention to environmental protection and energy efficiency increases, along with the growth demand in the new energy industry such as thermal energy utilization and electrical equipment, the application range of FFKM continues to expand.

Data-Driven Trend Analysis

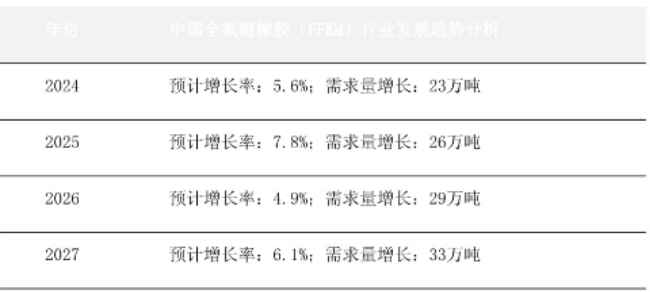

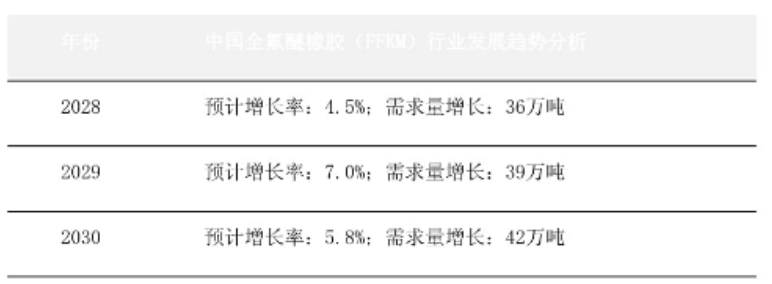

According to data from the Chinese perfluoroether rubber market, the annual growth rate has remained between 6% and 8% over the past few years. It is expected that this trend will continue over the next 57 years, mainly driven by the following factors:

1. New energy and clean energy technologies: As global investment in renewable energy increases, especially in the expansion of solar and wind energy, the demand for FFKM as a key material will grow significantly.

2. Chemical and petrochemical industries: The upgrades and technological advancements in these industries require support from high-performance materials, including performance requirements in corrosion resistance and high-temperature resistance, providing a stable market demand for FFKM.

3. Automotive industry: With the popularity of electric vehicles and the increasing demand for high-performance components in traditional vehicles, perfluoroether rubber, as one of the important materials for seals and oil seals, is expected to continue benefiting from growth in this field.

Investment return rate forecast

Based on the analysis of the above market trends and driving factors, it is expected that the overall investment return rate of the FFKM industry in China will remain at a high level over the next 5-7 years.

Specifically: Short-term (2024-2030): Considering the industry growth rate and the improvement of existing technology levels, the expected investment return rate is between 12% and 18%.

High-potential subfield forecast:

New energy vehicles: With the booming development of the electric vehicle industry, the demand for FFKM will significantly increase, especially in applications such as battery packaging and thermal management systems. The expected investment return rate can reach over 20%.

Chemical and petrochemical equipment: Driven by upgrades and environmental protection requirements, the demand for high-performance material replacements is rising, especially for perfluoro rubber that can resist corrosion and high temperatures, with an expected investment return rate between 15% and 20%.

High-end medical field: With the development of biomedical engineering, the demand for FFKM as a medical material is growing, especially in applications in implants and medical devices. The expected investment return rate is between 16% and 22%.

Task communication

During the in-depth research process, accurate interpretation of key data and precise analysis of industry trends were ensured to meet the requirements and objectives of the report. Please feel free to discuss and confirm content details or contentious issues to jointly promote the high-quality completion of the task.

Entry strategies: Technological cooperation, market expansion, etc.

Technological cooperation is one of the key forces driving industry development. With the growth of market demand and technological advancements, joint research and development and project cooperation with leading technology providers at home and abroad can accelerate product innovation, improve production efficiency, and enhance product quality. Especially in the research and development of high-performance perfluoroether rubber materials, introducing advanced production technologies and optimizing process flows can effectively enhance product performance indicators to meet the high demands of the high-end market.

In terms of market expansion, the huge domestic market demand in China provides broad opportunities. Government policy support for the manufacturing industry, as well as widespread applications in new energy vehicles, electronic devices, and medical devices, have created conditions for the growth of demand for perfluoroether rubber. By establishing close connections and cooperation models with downstream application industries, companies can more accurately grasp market demand trends and optimize product line layouts.

In predictive planning, the industry should focus on the following directions to maintain competitiveness:

1. Green manufacturing: With the enhancement of environmental awareness and policy guidance, adopting renewable materials, improving resource utilization efficiency, and reducing carbon emissions during the production process have become an inevitable trend in the development of the perfluoroether rubber industry. Investing in the research and application of green manufacturing technologies can not only respond to the development requirements of the international green economy but also reduce costs and enhance market competitiveness in the long term.

2. Intelligent production: The deep integration of automation and digitalization is an important way to improve production efficiency and ensure product quality. By introducing Industry 4.0 technologies, achieving intelligent scheduling, real-time monitoring, and data analysis of production lines can not only enhance production flexibility but also reduce the impact of human errors and optimize supply chain management.

3. International market expansion: With the increasing global influence of China's manufacturing industry, perfluoroether rubber products should actively layout overseas markets, utilizing international cooperation platforms such as the "Belt and Road" initiative to expand export business. This not only helps to increase market share but also enhances product technology and service levels through feedback from international markets.

4. Diversification development strategy: In the face of fierce competition and market changes within the industry, companies need to actively explore diversified development paths, including but not limited to investing in new material research and development, exploring emerging application fields (such as environmental protection, biomedical engineering, etc.), and enhancing supply chain resilience. Diversification can not only disperse risks but also maintain growth momentum in different market cycles.

Keywords: "2024 to 2030 Deep Analysis and Development Trend Research Forecast Report on China's Perfluoroether Rubber (FFKM) Industry"

RELATED INFORMATION

Company Information

Industry Information

-

Semiconductor commonly used parts - perfluoro O-ring (Dupont/GT...)

Time:2025-05-28

-

Standard requirements for high-performance perfluoroelastomer seals

Time:2025-05-13

-

SEMICON 2025 - Hongxin Fluoroethers Invites You to View the World's Largest Semiconductor Exhibition!

Time:2025-03-19

-

"2024 to 2030 Deep Analysis and Development Trend Research Forecast Report on China's Perfluoroether Rubber (FFKM) Industry"

Time:2025-01-17

-

Dry etching and wet etching in semiconductor etching film processes are suitable for different specific scenarios. 1. **Dry Etching**: - **Applications**: Typically used for high-resolution patterning, such as in the fabrication of integrated circuits (ICs) and microelectromechanical systems (MEMS). - **Advantages**: Provides better control over etching profiles, allows for anisotropic etching (vertical etching), and is suitable for etching complex geometries. - **Common Techniques**: Reactive Ion Etching (RIE), Deep Reactive Ion Etching (DRIE), and Plasma Etching. 2. **Wet Etching**: - **Applications**: Often used for bulk material removal, cleaning, and in processes where isotropic etching is acceptable, such as in the fabrication of certain types of sensors and optical devices. - **Advantages**: Generally simpler and less expensive than dry etching, and can be more effective for certain materials. - **Common Techniques**: Acid or alkaline solutions are used to etch materials like silicon, silicon dioxide, and metals. In summary, dry etching is preferred for applications requiring precision and complex patterns, while wet etching is suitable for simpler tasks and bulk material processing.

Time:2025-01-08

-

Typical semiconductor component: Vacuum system (1)

Time:2024-12-09

-

How to buy the right size perfluoroether rubber special-shaped seal ring

Time:2024-03-28

-

Maintenance methods and precautions of perfluorinated ether rubber special-shaped sealing ring

Time:2024-03-20

-

Analysis of Application Prospect of Perfluorinated Ether O-ring in Aerospace Field

Time:2024-02-14

-

Application and Development of Special-shaped Seal Ring in Oil Exploitation Technology

Time:2023-12-26

-

About the installation knowledge of perfluorinated ether O-ring

Time:2023-12-21

-

Where are perfluorinated ether O-rings widely used?

Time:2023-11-06

-

What is the difference between perfluoro rubber and perfluoro ether

Time:2023-09-14

-

The difference between perfluoroelastomer flange center ring and ordinary flange center ring

Time:2023-07-17

-

What is perfluoroether rubber? What are the characteristics of perfluoroether sealing products?

Time:2023-07-11