Semiconductor commonly used parts - perfluoro O-ring (Dupont/GT...)

Category: Industry Information

Time:2025-05-28

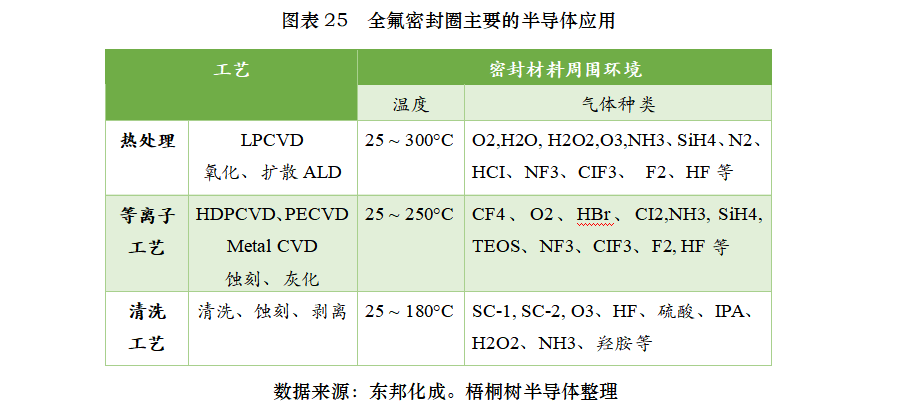

Perfluoro seals are one of the five main consumables required for the production of integrated circuits, and the current domestic self-sufficiency rate is less than 1%. In semiconductor production processes, there are often situations where fluorine-containing and hydrogen-containing gases encounter high temperatures. Without seals, high-energy gas flow contacting the surface of the modified material will cause severe corrosion of the material surface.

Perfluoroether rubber can withstand corrosion from more than 1600 kinds of chemical solvents, including strong acids, strong alkalis, organic solvents, superheated steam, ethers, ketones, esters, nitrogen-containing compounds, hydrocarbons, alcohols, aldehydes, furans, and amine compounds. It can withstand high temperatures of 320°C. FFKM perfluoroether components have nearly 40 years of practical application experience in numerous industries. FFKM is often used in semiconductor industry applications such as plasma etching, gas corrosion, acid-base corrosion, high-temperature corrosion, and high-cleanliness requirements for rubber sealing.

FFKM ( Perfluoroether rubber ) is the preferred material for semiconductor sealing. It is made by copolymerizing specific monomers and has excellent properties such as high temperature resistance, chemical corrosion resistance, and oil resistance. It is widely used in many fields such as aerospace and aviation, and has decades of application experience in the semiconductor industry. It is the rubber material with the best tolerance and provides a reliable sealing solution for the special environment of semiconductor manufacturing.

However, the current FFKM market is facing a severe shortage. The global total demand is approximately 200 tons, while the actual output is only between 150 and 180 tons, and the supply shortage has led to continuously high raw material prices. Moreover, due to restrictions imposed by PFAS regulations, many foreign companies' production is limited. For example, 3M will exit the field in 2025, and many Solvay and Daikin factories in Europe, North America, and Japan often face fines or production suspensions due to environmental issues. This has greatly challenged the supply stability of FFKM, casting a shadow over the global semiconductor industry supply chain. However, it is precisely against this backdrop that the independent breakthroughs of domestic enterprises are particularly crucial and urgent.

The general operating temperature is 260-290℃, and it can be used intermittently at high temperatures of 316℃. Perfluoroether rubber also has plasma resistance. It has the characteristics of high cleanliness and low outgassing in a plasma environment and can withstand plasma bombardment for a long time.

(Note: A indicates less than 10% swelling (including no swelling), and the medium has little effect on the rubber performance; B indicates a volume swelling rate of 10-20%, and the material's performance is affected to a certain extent, but it is basically usable, although the product life may be shortened; C indicates that the material has poor tolerance to the medium and needs to be analyzed based on the actual situation to determine whether it can be used; D indicates that the material cannot be used in this medium environment.)

In a plasma environment, it exhibits high cleanliness and low outgassing characteristics, can withstand plasma bombardment for a long time, meets the semiconductor industry's requirements for high purity and low impurities, and avoids the impact of material outgassing on the semiconductor manufacturing process and product quality.

Relevant Manufacturers:

Dongbang Chemical, Suzhou Fuxin...

DuPont (Kalrez) in the United States has the largest global market share, accounting for approximately 40%-50% of the perfluoro seal market. The Kalrez series is known for its high temperature resistance (long-term operating temperature up to 327℃) and low outgassing, and is widely used in key sealing applications of semiconductor equipment.

Together, DuPont and GT (Chemraz) in the United States account for 60%-70% of the global market share. The Chemraz series is specifically designed for semiconductor equipment and has outstanding resistance to plasma corrosion.

As the most expensive type of fluororubber, FFKM (perfluoroether rubber) is significantly affected by the complexity of raw material processes and the international supply chain. The following is the current market situation:

HALOPOLYMER, Russia: The Elaftor series FFKM raw rubber (models 1000, 1000P) from Russia, represented by Daohong Group, is priced at approximately 13,000-15,000 yuan/kg and is mainly used in high-end applications such as semiconductor seals.

Solvay: Tecnoflon PFR series FFKM raw materials (such as PFR 1075O, 95HT) are priced at approximately 13.7 yuan/g (i.e., 13,700 yuan/kg), meeting the standards of international high-end demand.

DuPont: Kalrez series products are sold in finished form, and raw materials are not sold externally. The estimated raw rubber cost exceeds 30,000 yuan/kg.

Daohong Group: The FFKM raw rubber produced by its subsidiary, Sichuan Hongxin Fluoroether Technology Co., Ltd., is priced lower than imported products, at approximately 12,000-20,000 yuan/kg, and is mainly used in the semiconductor, petrochemical, military, and aerospace industries.

Fujian Yonghong: Possesses the R&D capabilities for all types of FFKM raw rubber, with prices slightly lower than international brands, but has not yet achieved large-scale production.

FFKM is synthesized by copolymerizing monomers such as tetrafluoroethylene and perfluoroalkyl vinyl ether. Only a few companies worldwide have mastered the core technology. International manufacturers (such as DuPont and Solvay) control raw rubber materials, and domestic companies need to import raw rubber from Russia or Japan for processing.

Domestic companies are making breakthroughs through both imported raw rubber processing and independent research and development, but high-end FFKM (such as semiconductor grade) still relies on imports, and the domestic production rate is less than 15%.

The national "14th Five-Year Plan" promotes the independent and controllable development of semiconductor materials and accelerates the application of domestic FFKM in etching equipment, vacuum chambers, and other scenarios.

Keywords: Semiconductor commonly used parts - perfluoro O-ring (Dupont/GT...)

RELATED INFORMATION

Company Information

Industry Information

-

Semiconductor commonly used parts - perfluoro O-ring (Dupont/GT...)

Time:2025-05-28

-

Standard requirements for high-performance perfluoroelastomer seals

Time:2025-05-13

-

SEMICON 2025 - Hongxin Fluoroethers Invites You to View the World's Largest Semiconductor Exhibition!

Time:2025-03-19

-

"2024 to 2030 Deep Analysis and Development Trend Research Forecast Report on China's Perfluoroether Rubber (FFKM) Industry"

Time:2025-01-17

-

Dry etching and wet etching in semiconductor etching film processes are suitable for different specific scenarios. 1. **Dry Etching**: - **Applications**: Typically used for high-resolution patterning, such as in the fabrication of integrated circuits (ICs) and microelectromechanical systems (MEMS). - **Advantages**: Provides better control over etching profiles, allows for anisotropic etching (vertical etching), and is suitable for etching complex geometries. - **Common Techniques**: Reactive Ion Etching (RIE), Deep Reactive Ion Etching (DRIE), and Plasma Etching. 2. **Wet Etching**: - **Applications**: Often used for bulk material removal, cleaning, and in processes where isotropic etching is acceptable, such as in the fabrication of certain types of sensors and optical devices. - **Advantages**: Generally simpler and less expensive than dry etching, and can be more effective for certain materials. - **Common Techniques**: Acid or alkaline solutions are used to etch materials like silicon, silicon dioxide, and metals. In summary, dry etching is preferred for applications requiring precision and complex patterns, while wet etching is suitable for simpler tasks and bulk material processing.

Time:2025-01-08

-

Typical semiconductor component: Vacuum system (1)

Time:2024-12-09

-

How to buy the right size perfluoroether rubber special-shaped seal ring

Time:2024-03-28

-

Maintenance methods and precautions of perfluorinated ether rubber special-shaped sealing ring

Time:2024-03-20

-

Analysis of Application Prospect of Perfluorinated Ether O-ring in Aerospace Field

Time:2024-02-14

-

Application and Development of Special-shaped Seal Ring in Oil Exploitation Technology

Time:2023-12-26

-

About the installation knowledge of perfluorinated ether O-ring

Time:2023-12-21

-

Where are perfluorinated ether O-rings widely used?

Time:2023-11-06

-

What is the difference between perfluoro rubber and perfluoro ether

Time:2023-09-14

-

The difference between perfluoroelastomer flange center ring and ordinary flange center ring

Time:2023-07-17

-

What is perfluoroether rubber? What are the characteristics of perfluoroether sealing products?

Time:2023-07-11